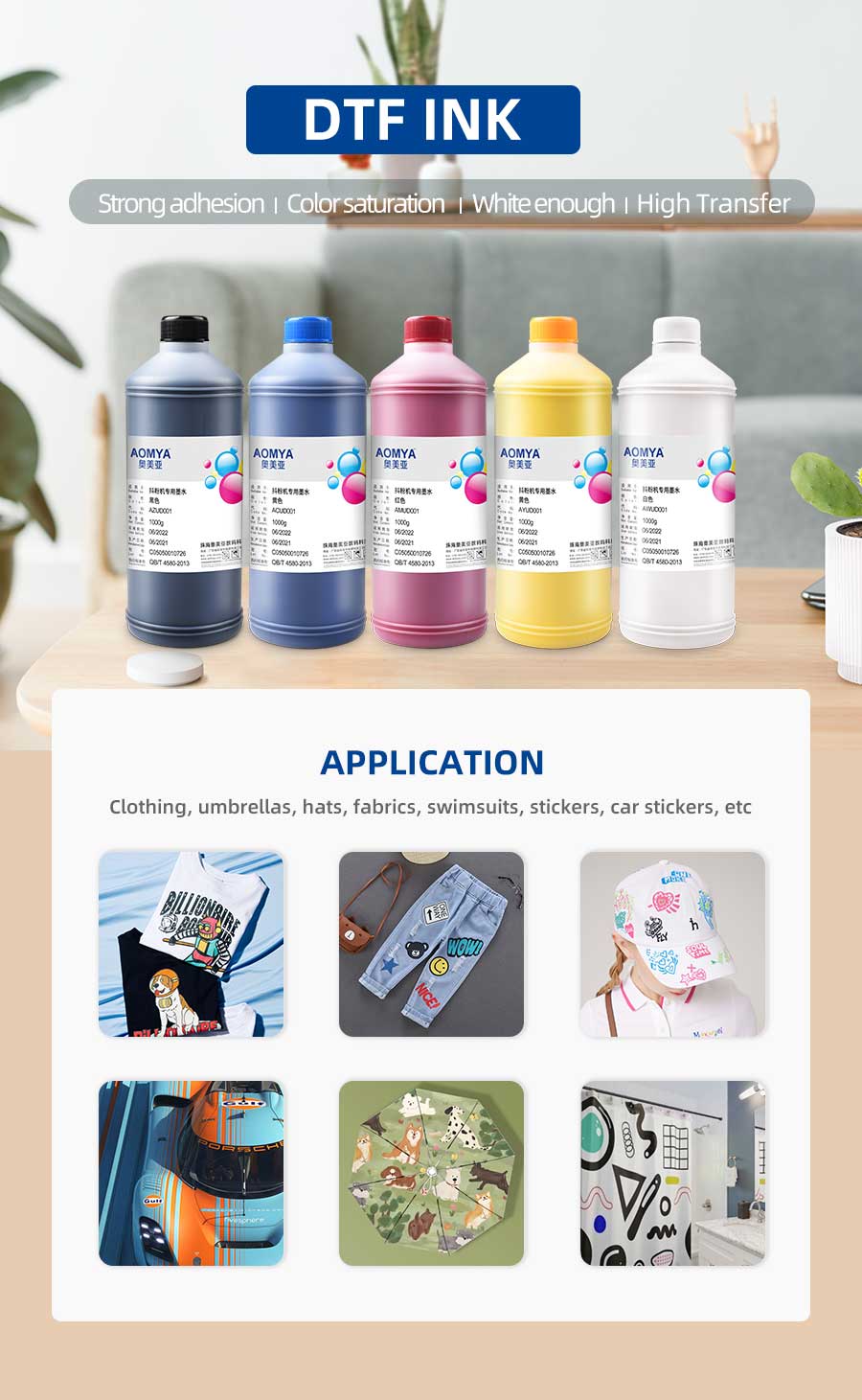

DTF Ink

Brand Name: DTF INK

Color: C,Y.M.K.W

Shelf Life: 12 months

Applications: Suitable for personalized clothing, leather, canvas bags, brand logos, etc.

Color: C,Y.M.K.W

Shelf Life: 12 months

Applications: Suitable for personalized clothing, leather, canvas bags, brand logos, etc.

DTF ink

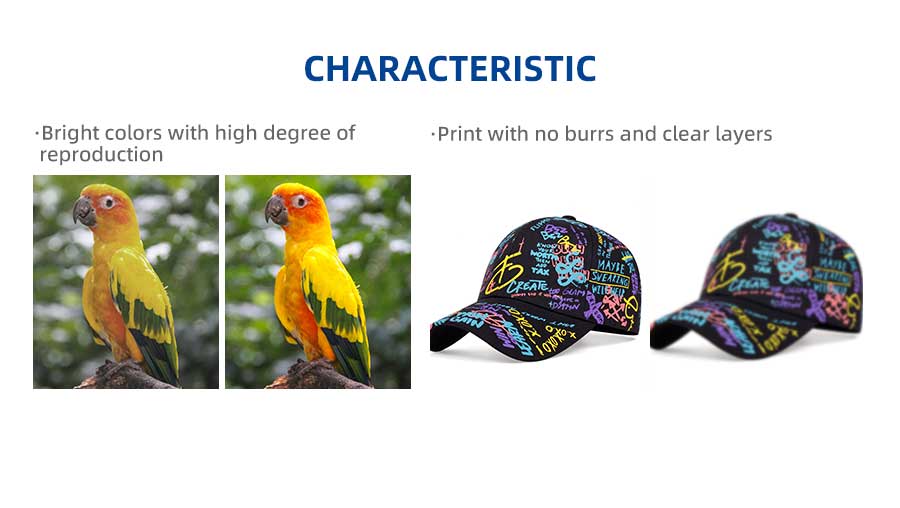

Features:

1.Bright colors, strong adhesion.

2.No preprocessing required, high production efficiency.

3.Environmentally friendly, suitable for complex designs and personalized customization.

Ink colors:

Cyan, Magenta, Yellow, Black, White

Suitable for print head:

For 3200-A1/XP600

上一个:

DTG Ink

(1).jpg)

.jpg)