Sublimation Ink for Industrial Heads

Color: BK, C, M, Y

Shelf Life: 12 months

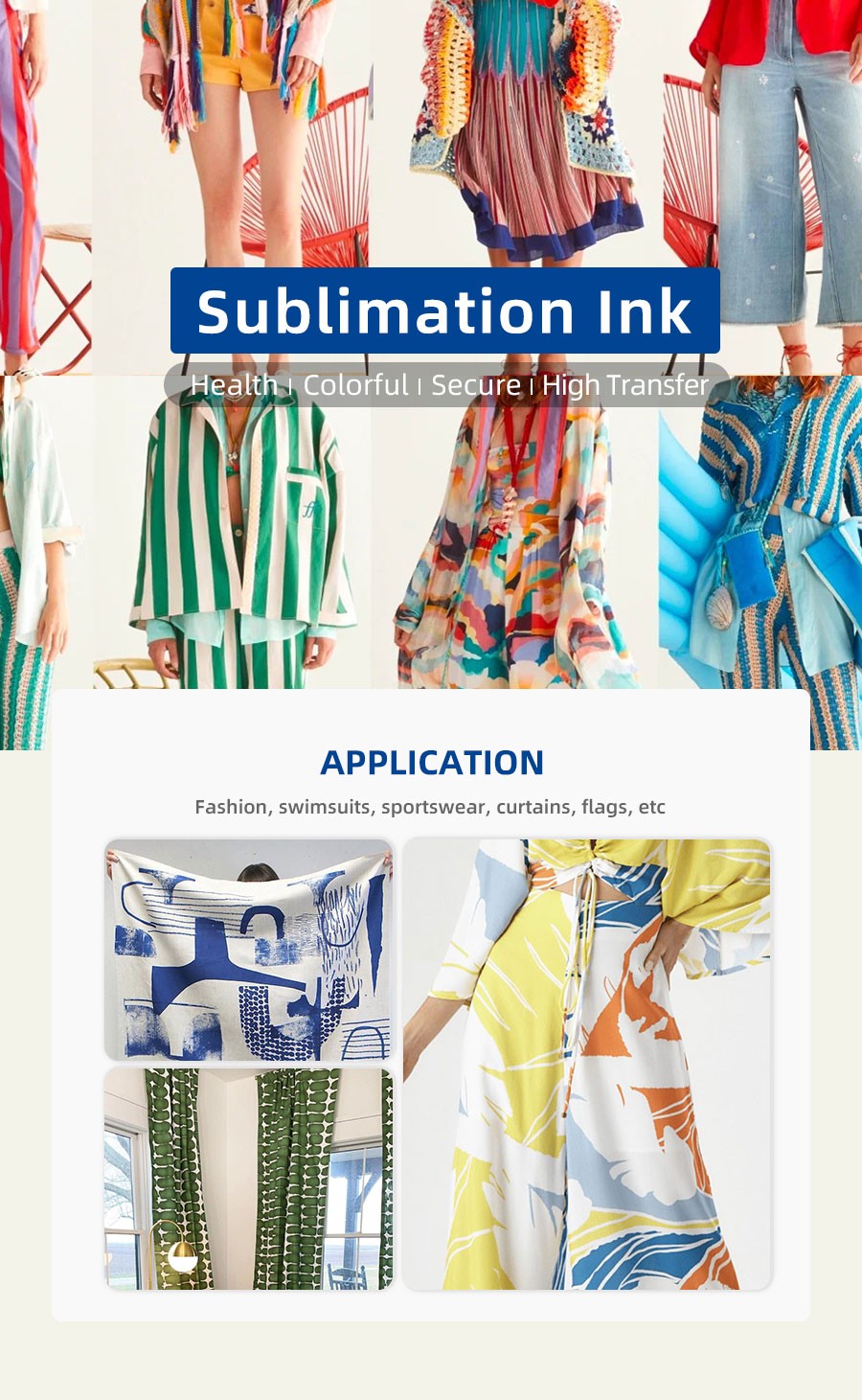

Application: Suitable for polyeste(fabrics with chemical fiber), for fashion,swimwear,sportswear,

curtains,flags, etc

Heat transfer printing ink is a new type of ink developed to adapt to the heat transfer printing process. The heat transfer printing process involves printing the pattern onto a plastic film coated with a release layer (mainly PET film) using a gravure printing machine, and then printing hot melt adhesive on the back of the pattern to form a heat transfer printing film. The printed heat transfer film passes through a heat transfer roller with a certain temperature and pressure at the heat transfer factory along with the final substrate before tearing off the film, and the pattern will be transferred onto the final substrate.

Sublimation ink Features:

1. Good fluency, not easy to block the nozzle.

2. The transfer image is bright in color and rich in layers, and its effect is comparable to that of printing.

3. At high temperature, the heat transfer ink is sublimated by heat, penetrates into the surface of the medium, and after condensation, the image can be formed.

4. It will not form a glue film on the surface of the medium, and the image will not fall off, not cracked, and it is very lightfast, and it will not fade for a long time.

(1).jpg)